Sustainable Materials and Manufacture

Our research tackles the pressing need for alternative materials and processes that can lead to low carbon performances and durability that compete with current petrol-derived resources. At QM’s Centre for Sustainable Engineering, we approach this challenge by:

- Combining innovative and scalable manufacturing techniques with advanced in situ / in operando characterisation methodologies that enable the design of highly functional materials based on sustainable and non-toxic earth abundant elements. These include oxide and sulphide-based thermoelectrics, lead-free dielectrics, metal halide perovskites for solar cells, biomass-derived carbons and recycled plastic for application in batteries.

- Development of new materials is supported by modelling methods, such as molecular dynamics, ab-initio and numerical modelling, and more recently, machine learning.

- Implementing life cycle assessment (LCA), our research aspires to design and develop materials with the lowest practical carbon footprint.

We actively collaborate with industry and engage with other academic institutions to maximise the impact of our breakthroughs and create an effective pathway to promote sustainable solutions to materials engineering. Our goal is to contribute to Net Zero and the Sustainable Development Goals through innovation in materials design and manufacturing processes, to build a greener future using sustainable resources.

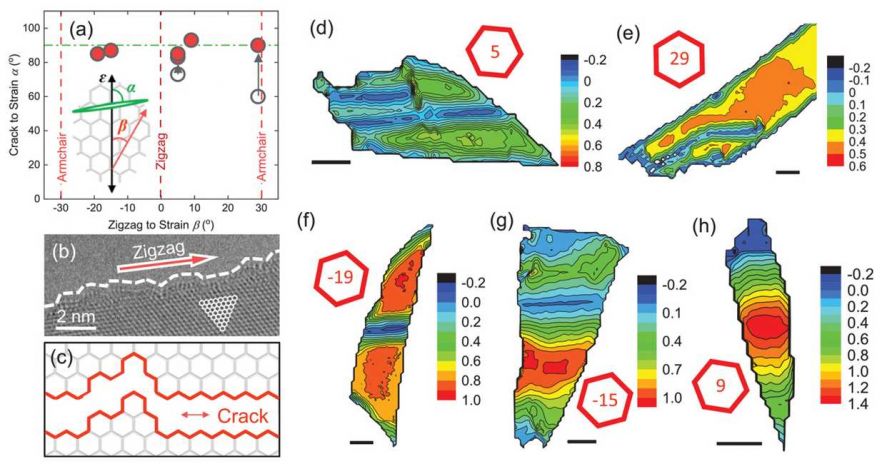

Imaging and modelling of crack propagation and stress fields in monolayer graphene through in situ Raman spectroscopy