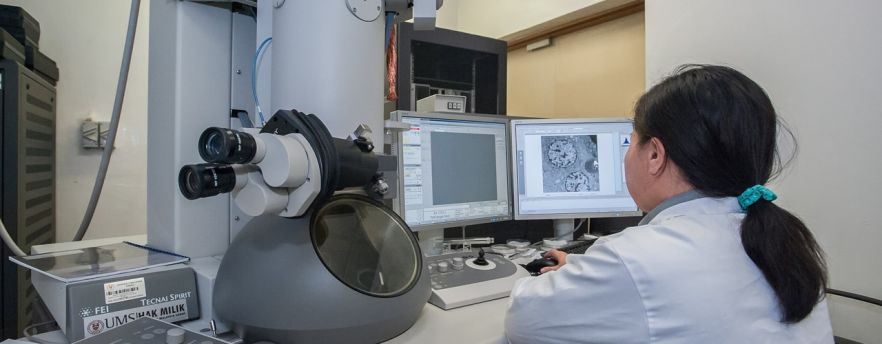

Research Facilities

The Centre for Intelligent Transport benefits from an excellent range of experimental facilities including manufacturing, robotics, materials characterisation as well asadvanced computational facilities. These facilities are also used for industrial contract testing and collaborations. Many of these facilities are shared with other research centres within the School of Engineering and Materials Science. In addition researchers within the school have access to many other specialised research facilities elsewhere in the university.